7:30 AM - 6:00 PM MON - FRI After Hours Contact Lee Osborne

Blog

Make a Precise Architecture With Stainless Steel Fabrication

Modern architectural stainless steel must be accurate, strong, and have a long service life. Today’s designers are concentrating on materials that retain their shape when stressed and that have good performance qualities in extreme environments. Clean lines that can be softened are pretty, and stainless steel really leads in that movement because you can work that look so beautifully while maintaining structural integrity. When it comes to commercial, residential, institutional, and industrial projects, the importance of stainless steel fabrication in Southwest Virginia cannot be overlooked in delivering strong, resilient construction that exceeds expectations.

Architectural accuracy begins well before the installation. Engineers and fabricators need to know about load, heat, corrosion, and wear. When it is formed with precision, stainless steel can be combined to meet these demands. Fabrication means you have to have precise measurements and skillfully make a controlled cut and weld. This is what allows for stainless steel to be incorporated into challenging designs while still maintaining equal strength and balance throughout.

Comprehending the Role of Stainless Steel Fabrication in Southwest Virginia

Local manufacturing serves projects requiring precision and regional expertise. Stainless steel fabrication in Southwest Virginia bridges your architectural intent with the reality of performance. Fabricators work closely with engineers to ensure that each component matches the design. They lean on established methodologies, such as forming, machining, and joining, to achieve repeatable results.

Precision architecture is also a function of how materials behave over time. Stainless steel withstands corrosion and retains its surface integrity in extreme environments. This enables it to be used in industrial plants, in infrastructure, and in high-technology plants.

Precision Architecture and Material Control

How does stainless steel influence what designers can make or do? Validation of work allows the cutting and shaping of steel to reduce the variation so that consistency can be achieved. This precise control enables seamless bonding with concrete, ceramics, and other manufactured materials.

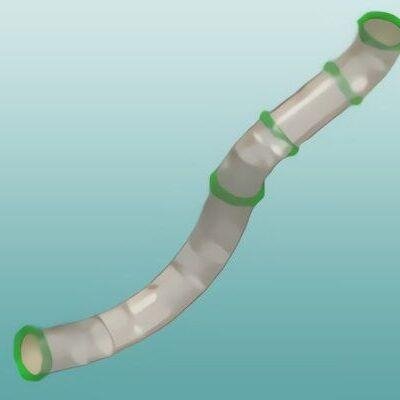

In industrial environments, precision is critical for safety and productivity. Pipe systems, enclosures, and structural supports must be squared and leveled to prevent leaks and stress points. Industrial pipe lining in Tennessee projects pairs stainless steel pieces that snugly fit into lined systems. With fabrication precision, such naval architectural connections can operate as designed without interruption.

Engineering Accuracy Through Fabrication Processes

Fabrication turns the raw material of stainless steel into functional components for the built environment. Each stage requires concentration and timing. Clean edges and tight tolerances can be achieved with cutting processes like laser or waterjet cutting. Bending processes form the steel without breaking it. Expert welding fuses parts without weakening or compromising the finish.

Quality control is still necessary throughout. Fabricators test dimensions and surfaces to verify. Such attention to detail facilitates architectural accuracy and long-term durability. When teams perform these core practices, they can expect their stainless steel structures to stand the test of time, literally for tens of years.

Integrating Stainless Steel With Advanced Surface Technologies

Many modern systems incorporate stainless steel with state-of-the-art surface treatment. Ceramic linings and protective coatings are employed with steel constructions to handle abrasion and corrosion. This interface is suitable for use in environments where particulates, heat, or chemical exposure are a concern.

Industrial pipe lining in Tennessee proves the importance of matched materials. Lining thickness, thermal expansion, and connection points have to be considered when fabricating stainless steel. Precise fabrication ensures that lined systems fit correctly and operate smoothly within larger architectural or industrial designs.

Design Collaboration and Regional Expertise

Precision architecture relies on teamwork. The architect, engineer, and fabricator need to have a mutual understanding of the objectives and limitations. Local fabricators provide knowledge of local codes, climate, and industry standards. Fabrication of stainless steel in Southwest Virginia is informed by this comprehensive understanding, promoting effective planning and execution.

Fabricators not only modify designs to real-world conditions but also do so without altering the intent. They recommend changes that enhance manufacturability while maintaining the precision. This collaborative approach reduces delays and ensures that final structures reflect the original vision.

Sustaining Precision Over Time

Accuracy does not stop at the installation. Stainless steel frames must stay aligned and maintain their structural rigidity throughout their life span. Good fabrication enables this along the way by reducing stress concentrations and material fatigue. The service also depends on precision machining when they assess or alter systems.

In Tennessee industrial pipe lining facilities, the quality of their long-term performance is directly related to the degree to which the fitted components that support lined surfaces are well fabricated. Tight joints and solid supports also prevent movement, which could compromise linings. This stability helps protect the architecture and the process it supports.

Conclusion: Building Precision With Confidence

Precision engineering is based on materials and procedures that are accurate from beginning to end. Stainless steel fabrication in Southwest Virginia lives up to that promise with precision production and craftsmanship. When the design intent and the knowledge of fabrication are brought together within teams, structures with enduring performance and clarity are the result. Ceramic Technology Inc. continues to endorse this philosophy by combining material science, fabrication knowledge, and real-world solutions to challenges faced by today’s architects.

Get in touch with us by sending an email to info@ceramictech.com, or you can call us at (276) 701-7954 to find out how superior fabrication and enhanced material solutions can enable your next architectural or industrial project, bringing you confidence and clarity

Frequently Asked Questions

What makes stainless steel suitable for precision architecture

Stainless steel has a known strength, corrosion resistance, and dimensional stability. This is what enables fabricators to manufacture precise parts that will hold shape under load and environmental conditions.

How does fabrication affect architectural accuracy?

Fabrication is how close a material can be brought to a design specification. Precision cutting, forming, and welding guarantee “right the first time” installation of components.

Why does regional fabrication matter

Local knowledge from regional fabricators matters a lot. Their expertise facilitates responsive coordination and dependable results on local projects.

How does stainless steel work with ceramic linings

The stainless steel provides strength; the ceramic linings protect from abrasive wear. The fit and long-term performance of both materials are guaranteed through accurate fabrication.

What role does quality control play

Quality control checks with the dimensions, finishes, and weld integrity. This ensures that the parts that are made fulfill the function of the design.