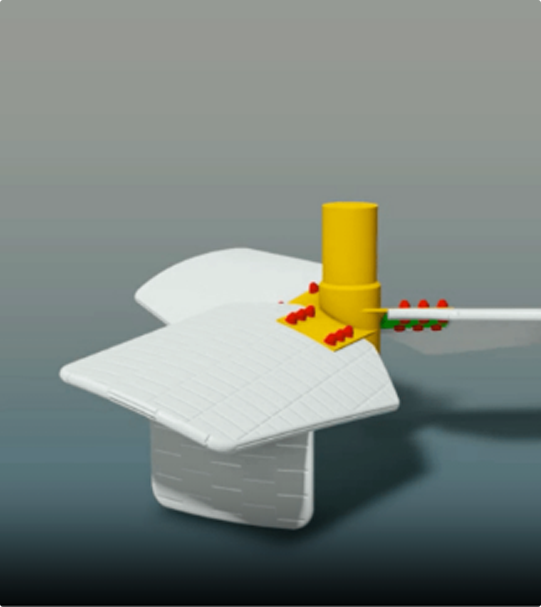

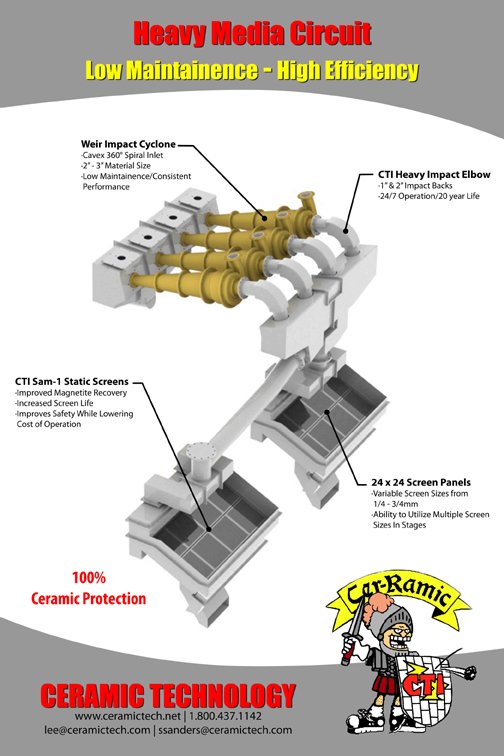

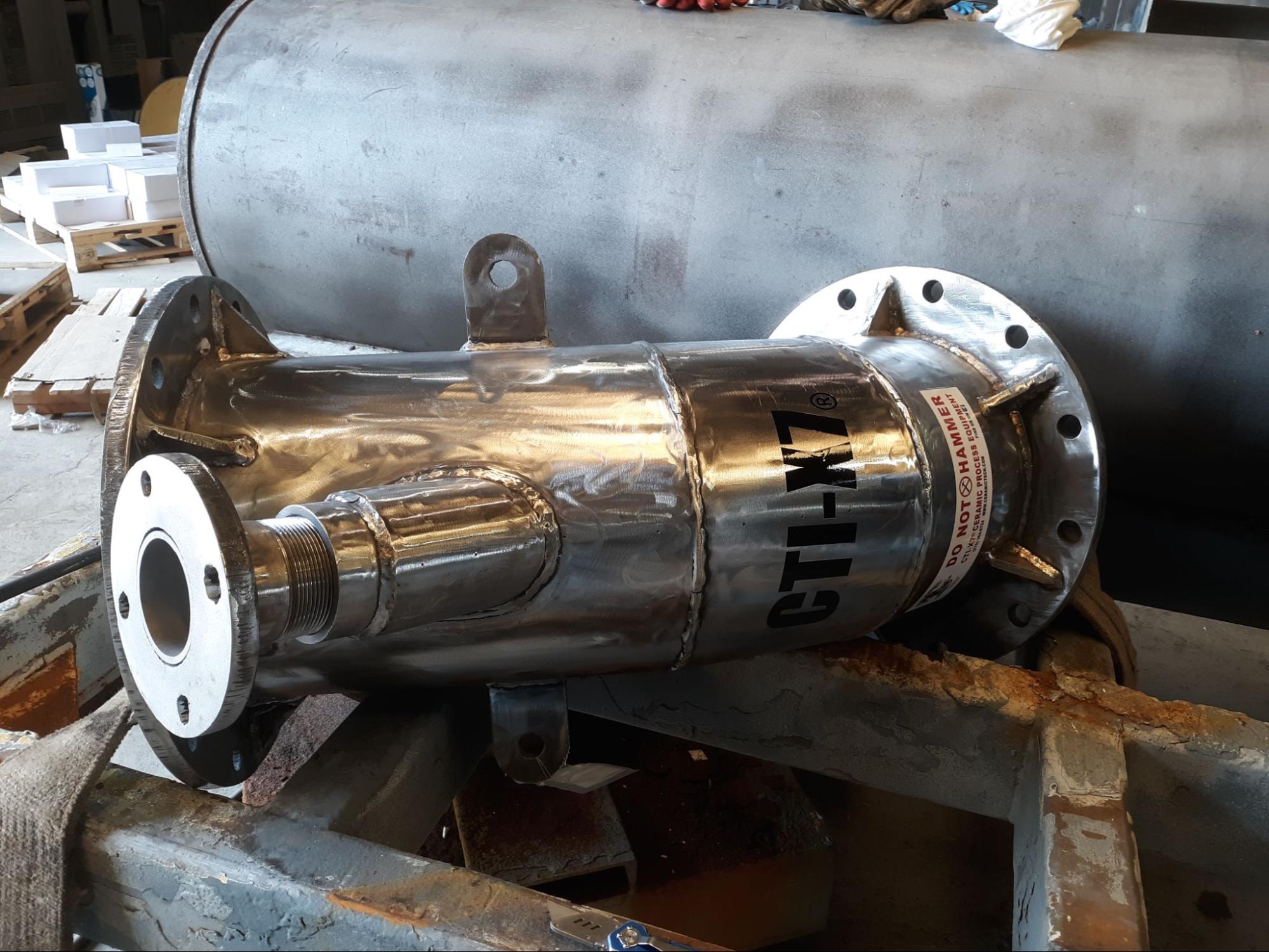

The CTI-X7® Performance Standard

It is a benchmark performer as applied to new process facilities or plant expansions to improve maintenance costs. Our equipment can also be used in existing operations to improve maintenance procedures or replace operational equipment.