Maintaining an efficient mining and mineral processing operation is essential to maximizing production while minimizing costs. Many factors must be considered when improving efficiencies, such as plant maintenance, process optimization, and emergency management.

Ceramic Technology Inc. (CTI) is a global leader in providing new capital and plant expansion equipment that improve efficiency while reducing costs. Our team of experts has years of experience in the mining and mineral processing industry, and we are committed to helping you achieve your goals.

Plant Maintenance

Maintenance is an integral part of any operation, but it is especially critical in mining and mineral processing. It is essential to have a well-designed maintenance plan to maximize production and reduce costs. Having a maintenance foreman coordinate proper plant maintenance can avoid costly downtime and keep your operation running smoothly.

When you reach out to our team for plant maintenance, our sales and service engineers go onsite and discuss the equipment or replacement parts needed with the customer. Our engineering staff does a preliminary drawing for your review and approval, then a quote for your final review and approval. In most cases, the equipment will ship within 4-6 weeks.

Process Optimization

Another way to improve efficiency is by optimizing plant processes, which may involve redesigning the plant layout or installing new equipment.

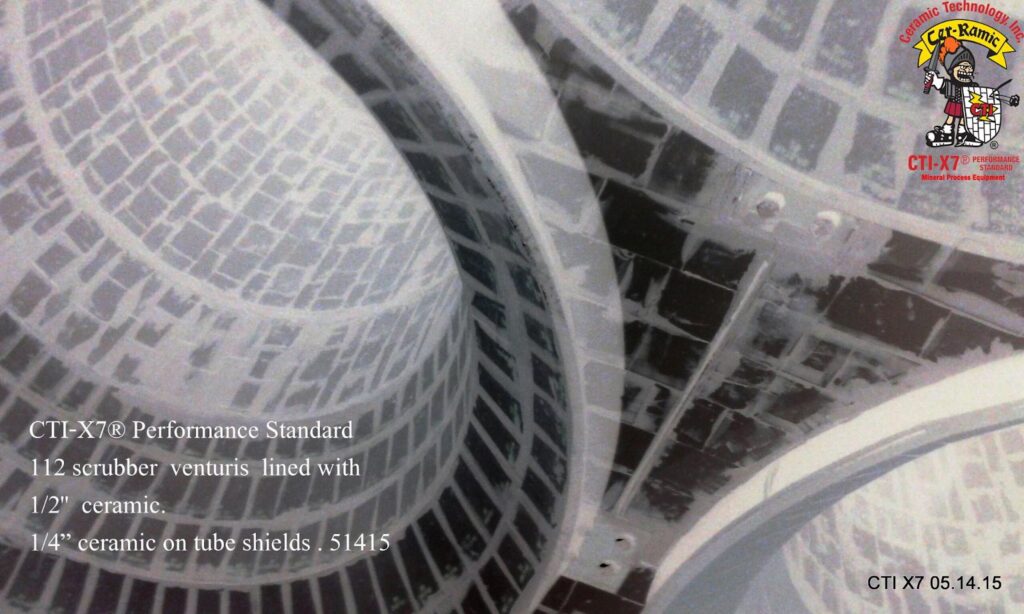

The CTI-X7® Performance Standard is a benchmark performer applied to new process facilities or plant expansions. Plants can also use our equipment in existing operations to improve maintenance procedures or replace operational equipment. This leads to better plant performance and fewer maintenance issues.

Emergency Management

In the event of equipment failure or process upset, it is essential to have a plan to quickly and safely shut down the affected area while minimizing production losses. A well-designed emergency management plan can avoid costly downtime and keep your operation running smoothly.

You can avoid emergency shutdowns by upgrading your plant processing with our CTI-X7 solutions. The CTI-X series is designed for maximum uptime and reliability while reducing maintenance costs.

If you are looking to improve your plant’s efficiency and bottom line, contact us today. We can help you create a custom solution to maximize production while reducing costs.

The Importance of Mining and Mineral Processing

Mining and mineral processing are integral parts of our everyday lives. They are the economy’s building blocks, providing the raw materials for construction, manufacturing, and other industries.

Despite their importance, mining and mineral processing operations are often plagued by inefficiencies. This can lead to increased costs, lower production levels, and lost opportunities.

Benefits of Increased Efficiency

There are many benefits to be gained from increased efficiency in mining and mineral processing:

- Increased production levels: By increasing efficiency, mining and mineral processing operations can increase production levels while reducing costs. This can lead to more revenue and better bottom lines.

- Reduced repair costs: More efficient equipment can lead to reduced repair costs. Less downtime due to regular maintenance and better equipment means less need for repairs.

- Improved safety: Efficiency gains often go hand-in-hand with improved safety. This is because fewer stoppages mean fewer opportunities for accidents to occur.

What We Do

For coal, phosphate, potash, and gold mining operations in the United States and Canada, CTI provides new mining plant expansion, equipment design, and maintenance fabrications. CTI’s X7® Standard OF Performance establishes a 20-to-1 return on investment for new capital plant and expansion equipment and provides an X7® Redesign Standard that promotes better maintenance.

Our sales engineers collaborate with your plant superintendent or maintenance foreman to target and deliver precise, ceramic-lined fabrications and ceramic pipe fittings on time, resulting in better mining operations.

How We Can Help

Ceramic Technology Inc. has been helping mining and mineral processing operations improve their efficiency for over 35 years. We offer a wide range of products and services that can help you increase productivity while reducing costs, starting with our knowledge in the coal mining sector and ceramic pipe fittings. Our experienced team can work with you to find the right solution for your needs.

We offer a wide variety of professional services as the sole contract manufacturer of CTI-X7® Ceramic Process Equipment. Our engineering team has created concepts for which many patents have been granted in the United States, Canada, and Australia.

Upgrade to CTI-X7® Today

Are you a maintenance foreman or plant superintendent looking for ways to increase production while reducing costs?

Our team can help you find the right solution for your needs, starting with our knowledge in the coal mining sector. Upgrading to our CTI-X7® Ceramic Process Equipment will allow you to take advantage of the latest mineral processing technology and improve your process efficiency. Contact us today to learn more about how we can help you maximize productivity while reducing costs.