Posts by Ceramic Technology

Boosted Productivity With CTI-X7Ⓡ

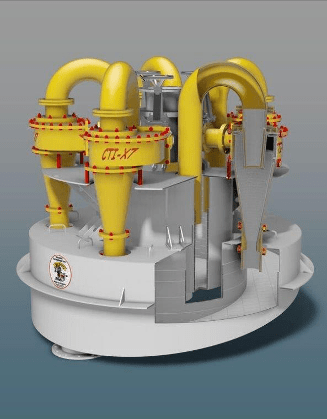

Ceramic Technology, Inc specializes in producing outstanding ceramic redesigns that use the most advanced mineral processing technology available. The CTI-X7 is a game-changing tool for mineral processing. Our patented ceramic lining can benefit plant components, resulting in a productive workflow that operates twenty-four hours a day, seven days a week. About the Ceramic Process Equipment…

Read MoreCeramic Lining: The Benefits of Reducing Impact and Corrosion

Mineral processing produces a lot of corrosion and abrasion on materials, especially those that tend to be weaker. Many pieces of plant equipment only tend to last for several years, which can cause potential inconveniences for plant managers. The common question then occurs, how to prevent corrosion? Also, plant equipment has grown more expensive over the…

Read MoreComparing Ceramic Lining to Rubber and Polyurethane liners: How the CTI-X7Ⓡ Performance Standard Resists Abrasion

Polyurethane liners are widely used in processing plants. With many components and materials coming together in mineral processing it is important to ensure that all systems function as intended. Routine assessments of where your losses are and changes when necessary must be done to improve a plants bottom line. It has been shown that ceramic…

Read MoreEngineering Ceramic Process Equipment

How Ceramic Engineering Plays a Role in Continuous Production Ceramic Engineering provides continuous production which is pivotal to plant performance in mineral processing, especially in the gold and coal mining industries. When a plant operates under 24 x 7 continuous production capabilities, it allows for a higher ROI for plant managers and crews, allowing teams…

Read MoreImprove Your Plant Processing Equipment Longevity with CTI-X7Ⓡ

At Ceramic Technology, our team works hard to find new ways for plant processing managers to improve productivity in their plants. We understand that many of the materials that teams process daily include coal, gold, and other metal alloys. Over time, these materials can wear down traditional equipment, leading to abrasion and corrosion. These problems…

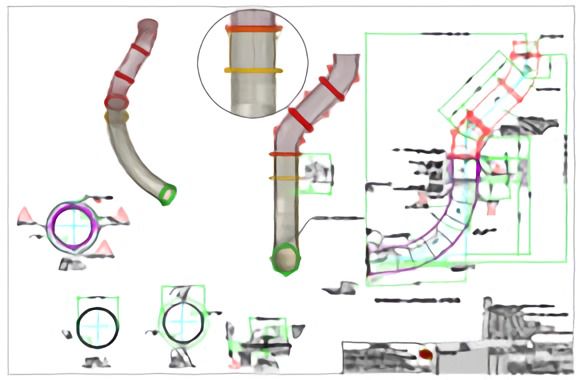

Read MoreDesigning Effective Impact Elbows for Usage In Mineral Processing

Engineering capital equipment and mineral processing tools is highly specialized work. When people design and create mineral processing equipment, they should have many factors in mind. These factors include, but are not limited to, flow rate, material utilized, processing speed, and lining. These systems must see usage 24 hours a day and seven days a…

Read MoreCeramic Technology’s Contract Manufacturing Services

How They Impact Plant Performance Ceramic Technology, Inc. has worked very closely with plant managers since we started in 1985. We have worked diligently to innovate on plant equipment and provide plant managers with the materials they need to improve their equipment and generate a significant return on investment. Our contract manufacturing services are a…

Read MoreThe Benefits of Custom Fabrications

Why Use Custom Fabrications? Custom fabrications and industrial pipelining can help improve plant efficiency and durability. These fabrications give plant managers the tools they need to improve production. We understand that capital production materials cost a lot of money for plants to maintain. For this reason, it can seem devastating to a plant manager when…

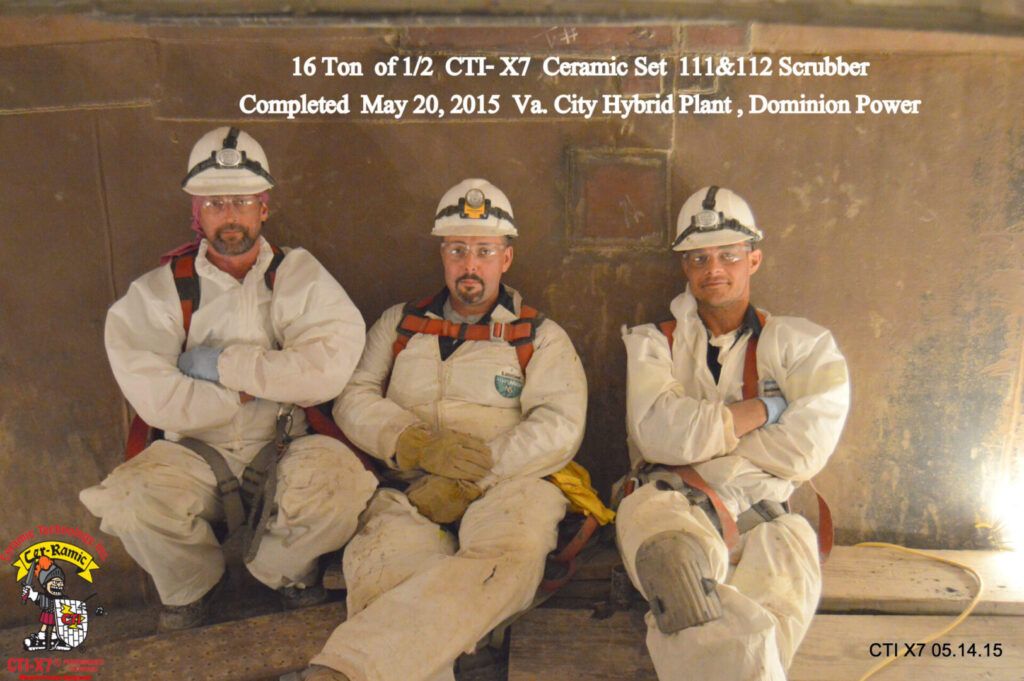

Read MoreIndustrial Plant Maintenance with Ceramic Technology, Inc.

Industrial plant maintenance is an essential part of improving the efficiency of a mineral processing facility. Maintaining a safe environment allows operators to work securely. Maintaining occupational Safety can pay you in the long run. Mining operations and industrial plants can have the most to gain. So it is important to have safety and maintenance…

Read MoreWhy Are Maintenance Support Kits Important?

Short answer is, Industrial maintenance support kits saves time by having all the parts required and present to complete the install. That way you don’t have to send runners to collect bolts, etc. The downside of waiting until the last minute is runners discover bolts and other required items are not in the warehouse. This…

Read More