Posts by Ceramic Technology

The Inner Workings of Steel Fabrication

Have you ever wondered how steel fabrication works? The process is intriguing, intricate, and the end product is truly impressive. Taking a look at the inner workings of steel fabrication, from start to finish, you’ll learn about the three main processes of steel fabrication as well as additional processes. Here at Ceramic Technology, we offer…

Read MoreHow CTI-X7® Advanced Chute Systems Can Help Improve Mining Efficiency

Mining is a vital part of the economy, and it’s crucial that mines operate as efficiently as possible to ensure that resources are extracted in a timely and profitable manner. It is also a highly competitive industry, with companies constantly striving to outperform their competitors. This means that even minor improvements to equipment like advanced…

Read MoreWhy You Need Industrial Maintenance Service

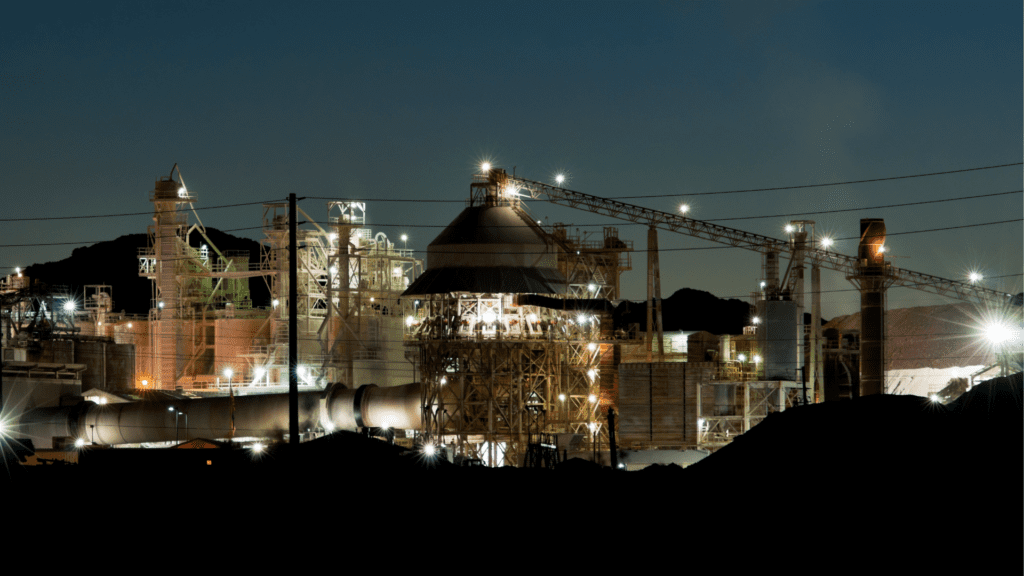

Running and maintaining a mineral processing plant is a huge undertaking. It can be a 24/7 operation, and any downtime can result in lost production and profits. That’s why it’s essential to have a reliable industrial maintenance service that you can count on to keep your plant running smoothly. It’s not a luxury — it’s…

Read MoreAlumina Oxide: It’s What Makes Us Stronger

Alumina ceramic (also known as Aluminum Oxide or Al2O3 ) is the backbone of our wear-resistant ceramic lining services. When using alumina ceramic lining, material processing equipment life can be extended by as much as 20:1 on material processing systems such as piping, chutes, cyclones, overflow underflow boxes, distributors, head chutes, load-outs, feeders, etc. But…

Read MoreLearn How Industrial Plant Maintenance Can Help Increase Efficiency

Industrial plant maintenance is vital to keep operations running smoothly and efficiently. Operators can avoid unexpected downtime and keep production levels high by ensuring that all equipment is maintained correctly. Explore some ways industrial plant maintenance can help increase efficiency, including the most common maintenance tasks that must be performed regularly. What Is Industrial Plant…

Read MoreThe Benefits of Ceramic Lining Services for Cyclones and Pipings

Cyclones and pipings are important industrial components that must be kept in working order. One way to do this is by using ceramic lining services. Ceramic liners can protect cyclones and piping from degradation and extend the equipment’s life. By using ceramic lining services, you can improve your system’s performance while ensuring its safety. Cyclones…

Read More