Uncategorized

Uncategorized

Engineering Ceramic Process Equipment

By Ceramic Technology |

How Ceramic Engineering Plays a Role in Continuous Production Ceramic Engineering provides continuous production which is pivotal to plant performance ...

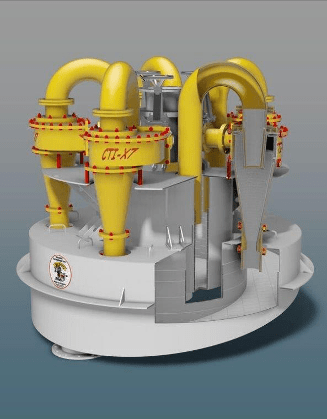

Read More Improve Your Plant Processing Equipment Longevity with CTI-X7Ⓡ

By Ceramic Technology |

At Ceramic Technology, our team works hard to find new ways for plant processing managers to improve productivity in their ...

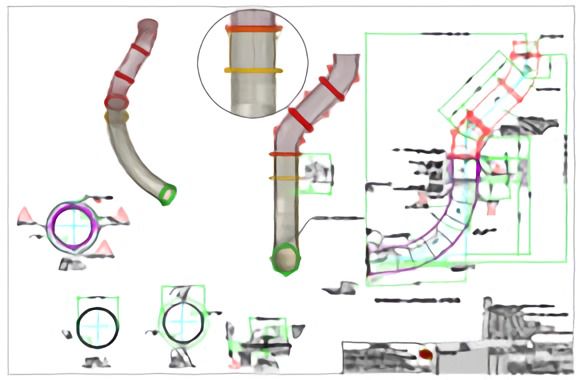

Read More Designing Effective Impact Elbows for Usage In Mineral Processing

By Ceramic Technology |

Engineering capital equipment and mineral processing tools is highly specialized work. When people design and create mineral processing equipment, they ...

Read More Ceramic Technology’s Contract Manufacturing Services

By Ceramic Technology |

How They Impact Plant Performance Ceramic Technology, Inc. has worked very closely with plant managers since we started in 1985. ...

Read More The Benefits of Custom Fabrications

By Ceramic Technology |

Why Use Custom Fabrications? Custom fabrications and industrial pipelining can help improve plant efficiency and durability. These fabrications give plant ...

Read More Industrial Plant Maintenance with Ceramic Technology, Inc.

By Ceramic Technology |

Industrial plant maintenance is an essential part of improving the efficiency of a mineral processing facility. Maintaining a safe environment ...

Read More Why Are Maintenance Support Kits Important?

By Ceramic Technology |

Short answer is, Industrial maintenance support kits saves time by having all the parts required and present to complete the ...

Read More Benefits of CTI-X7 Processing Equipment

By Ceramic Technology |

Ceramic Technology, Inc. has developed a variety of ceramic lining solutions for plant managers and employees. These equipment types have ...

Read More Improving Mineral Processing With Ceramic Equipment

By Ceramic Technology |

Ceramic lining shows marked improvements over rubber and urethane components. At Ceramic Technology, we have worked with ceramic lining and ...

Read More CTI-X7 Lining in Carbon and Stainless Steel Pipes

By Ceramic Technology |

Many mineral processing plants require a lining that reduces downtime and continuously processes materials. Our CTI-X7 lining can help plants ...

Read More